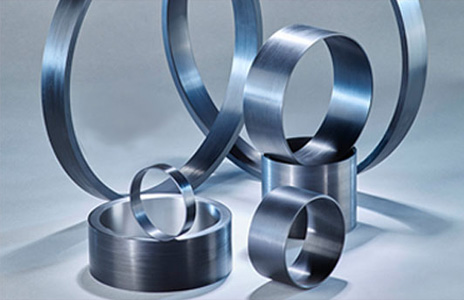

FilaWin® composite sleeves as reinforcement for electric rotors and generators are mainly used to retain magnets on high speed application.

Motor and generator units with composite sleeves are used in a variety of applications due to the need to improve speed and energy efficiency across all sectors. FilaWin® carbon fibre composites are the first choice for such applications as they have an excellent stiffness to weight ratio, strength to weight ratio and are easy to machine.

CirComp offers FilaWin® composite sleeves as tight fit solution, assembled by CirComp or assembled by the customer as well as composite sleeves applied by directly winding onto the rotors.

Composite retention sleeves offer the perfect technical solution as magnet retention sleeves due to their transparency for the magnetic field in combination with the high mechanical properties and low weight. CirComp manufactures and assembles FilaWin® composite retention sleeves as swell as composite rotor cans for a wide range of applications including high speed motor and generators for, KERS Systems and for turbo energy recovery systems.

Typical lot sizes for composite sleeve manufacturing at CirComp are between 1 rotor sleeve to over 100.000 rotor sleeves of one sleeve dimension. CirComp assist their customer in design of composite sleeves and offers a wide range of certified composite thermoset and thermoplastic materials from low temperatures (DW 230 material) up to maximum temperatures of 400 °C (DW260 material).

Also note our paper "High efficient sleeve applications".